As promised, here is the longer version of my about.com post on making beef jerky at home. Why make jerky? I like making jerky because I can buy beef in bulk, buy the good stuff, and choose my favourite flavours and still make it cheaper than the store-bought jerky – plus it doesn’t have any of those mystery ingredients in it. Or maybe you are a hunter and have some meat you’d like to use up in creative ways, jerky is a great option. Just make sure you follow the safety instructions here to kill anything that could potentially make you sick.

This recipe is for teriyaki beef jerky, but the same procedures may be used for the marinade of your choice. For a couple other marinade options and another detailed look at making jerky, check out Northwest Edible Life, one of my favourite blogs. Also, check out the publication that I refer to for safe jerky making linked here – PNW 632.

Ingredients

1.5-2 pounds of lean beef

1 cup soy sauce

1/3 cup brown sugar

1 tablespoon minced (or dry) garlic

1 tablespoon powdered ginger (or use fresh)

For the beef, I used a flank steak, but any lean cut is good. Chuck, flank, round, rump and sirloin are all good options, and most cuts of game meat are lean so it all works pretty well.

Partially freeze the beef to make it easier to cut. Wrap it in moisture-proof paper or plastic wrap and freeze until firm but not frozen solid. Trim off any excess fat. Slice the meat into long thin strips, an eighth to quarter-inch thick and about an inch wide. You can decide here whether to cut with the grain of the meat or across it. I prefer to slice with the grain because it’s easier to cut, holds together better and makes a chewier, less crumbly jerky. But try a few of each and see what you like best.

Prepare the marinade by combining everything except the beef.

So, here is the safety part. To ensure jerky is free of bacteria, it must be heated either before or after it is dried. There are three options for doing this:

1. Dry the jerky, and then heat it in the oven at 275°F for 10 minutes when it’s done

2. Preheat the meat in the oven at 325°F until an internal temperature of 160°F is reached before drying.

3. Preheat the meat in boiling marinade before drying.

Let’s look first at options 1 and 2 because for each of these options you will marinate the meat. Combine marinade and slices of meat in a plastic bag or glass dish and marinate in the refrigerator for 6-12 hours, turning the meat occasionally.

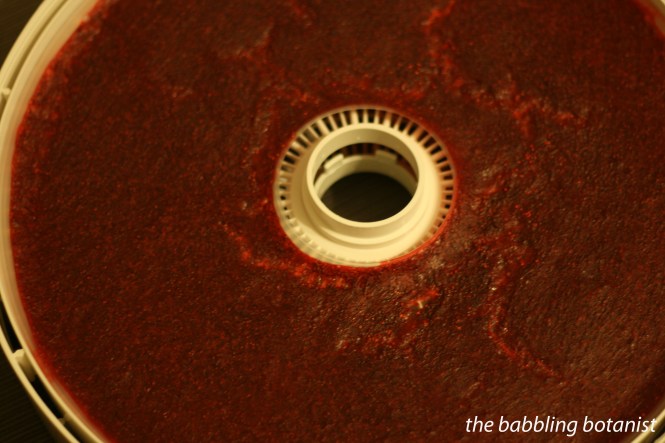

Once marinated, you have two options, dry, then heat; or heat, then dry. Option 1, the post-dry heat is probably the easiest one to do. In this case, remove the meat from the marinade and arrange your strips of meat on the dehydrator tray close together but not touching. You can pat them dry a bit if you like to speed up the drying time. Dry them until they are dry (duh – but I’ll explain how to tell in a minute).

Once the jerky is dry (sorry, the flash totally makes them still look wet), you’ll transfer them to a baking sheet and heat for 10 minutes in an oven preheated to 275°F. At this point your jerky is done. Cool it on a paper towel to absorb any excess fat and then store.

If you chose door number 2, you are precooking the meat basically. The oven needs to be a little hotter (325°F), and the meat needs to reach an internal temperature of 160°F. The disadvantage of this is that you really need a thin tipped thermometer to measure such a thin strip of meat. But if you already have one, or would use it for other purposes then great! This method also means less dehydrator time, and since you precooked you don’t have to worry about overcooking it with the 10 minutes at the end which I have felt I did with some ground meat jerky.

After your precook, dry the strips the same as above. (Yes, this picture is of raw jerky – didn’t have a precooked pic).

For the third option, do not marinate the meat. Instead, heat the marinade to boiling and add the beef strips a few at a time. Allow the marinade to return to a gentle boil and stir for about two minutes. Remove and repeat until all meat has been precooked, then immediately dry the meat. This precook method also has the advantage of a shorter dry time, and it was actually my MFP teacher’s favourite method, but I find it doesn’t have quite as strong a flavour as the marinade methods, and makes the meat a bit crumbly. But again, try all three and see what you like.

For all options, dry the meat either in a dehydrator or in the oven. Set the dehydrator to it’s highest setting (mine says 160°F, somewhere 145-155°F is what’s called for). Now I can’t vouch for how well it works in the oven because I have always used my dehydrator, but here’s how you do it. Arrange the meat on a baking sheet, and dry with the door propped open for airflow. Dry at 144-155°F. Now some ovens can’t maintain that low temperature, so make sure that your oven can maintain 145-155°F using an oven thermometer before even attempting jerky. Set the temperature, prop open the door , and monitor it for one hour. If it cannot maintain temperature, use a dehydrator. Trying to dry the meat with the temperature too high can result in the meat drying on the outside, but maintaining pockets of moisture on the inside. Moisture=bad!

Dry for at least 4 hours (oven drying takes longer and marinated jerky takes longer, and a fuller dehydrator takes longer) until the pieces of meat are dry. When dry, jerky should bend and feel leathery, but not snap. Remove a piece from the dehydrator, let it cool, and then bend it to test for dryness. If there are still moisture pockets, or if you are unsure, dry it a little longer. Most people judge it as done before it really is (including me last time I made this. I had to put them back on the dehydrator and that’s OK).

Once dry, cool on a paper towel, and then store in a cool, dark place. Since some pieces may be slightly wetter than others, you should also first condition them at room temperature for a couple days. Basically this just means leave them in a jar together and give it the occasional shake. If you notice condensation, you haven’t dried them enough – back to the dehydrator!

Jerky will keep for 2 weeks at room temperature, 3-6 months in the refrigerator or up to a year in the freezer. I usually don’t make a ton at a time so keep it in the fridge, but if you do a massive batch it’s nice to freeze some and take it out as needed.

For a comparison of the methods, I tried my best to capture how they came out. Between the two marinaded ones, I couldn’t tell a huge difference, but I could with the boiling marinade version. Here, the left picture is method 1, marinade and post-dry heat, and the right is method 3, boiling marinade. The boiled ones were a bit drier and more crumbly, and less strongly flavoured. But when I added spice on the outside they were very delicious. And Janice loves this method, so you decide! If you try multiple methods, let me know what you like best!

*this post contains affiliate links, please see the “About the Blogger” page for more information